Doğan Group’s Environmental Projects

For Doğan Group, environmental stewardship is crucial to ensuring the healthy future of humanity and nature. The Group conducts all activities in an eco-conscious manner, actively reducing its environmental impact.

All Doğan Group companies adhere to International Labor Organization (ILO) principles and universal human rights. Accordingly, they conduct all necessary evaluations and take measures to ensure their employees’ safety and security. We believe that stronger connections between nature and people leads to healthy and happy lifestyles. We can only leave future generations with a better world if we live in ways that respect our environment. Although the positive environmental contributions we make, as individuals or as a corporation, may at times seem trivial, we believe these efforts are ultimately highly valuable.

Doğan Holding

We closely follow current technological developments and regulations in order to ensure environmentally sustainable conditions in our administrative buildings and quickly implement the necessary projects. The Holding’s head office, in use since 2011, is equipped with new-generation cooling devices in line with EU norms, and these devices use the eco-friendly gases R 410 and R 132. The headquarters building is also equipped with a state-of-the-art, eco-friendly fire-extinguishing systems, and we have reduced the weight of individual fire extinguishers by replacing them with eco- and people-friendly systems that deploy FM 200 and Novac 1230 gases in compliance with EU standards. The insulation technology used in the building has led to a decline in natural gas consumption for heating and a drop in electricity consumption for cooling, resulting in a reduction in overall CO2 emissions.

Knowing that disposing organic waste has an adverse effect on climate change and causes environmental problems, we began recycling our garden waste. Thanks to our garden composting machine, the precious soil obtained from waste can be reused. Doğan Holdings’ commitment to composting food waste means that all organic wastes from our buildings will be recycled and used as fertilizer..

Energy

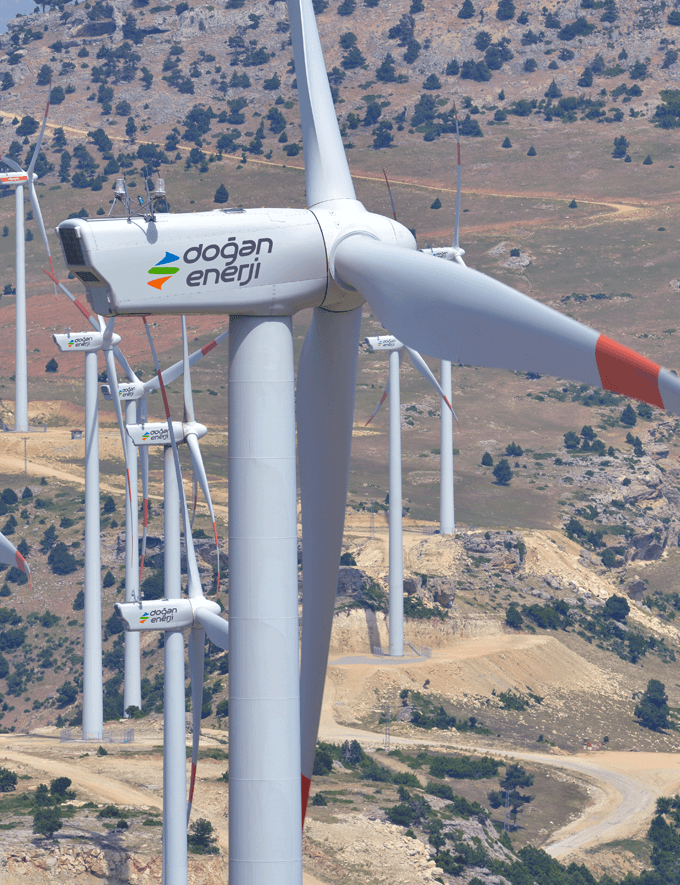

Doğan Enerji

Embracing legally compliant operations at all its plants, Doğan Enerji adopts environmentally friendly approaches across all its fields of operation. For all of its power plants, Doğan Enerji has obtained official authorization certificates and documents stipulated by the Law on Forests No. 6831, Regulation on the Licenses and Permits Required by the Law on Forests; Environmental Law No. 2872, Regulation on Permits and Licenses Required by the Environmental Law; Regulation No. 29274 on Procedures and Principles Governing the Signing of Water Consumption Rights Agreements for Generating Power in the Electricity Market; and Regulation No. 29865 on Electricity Market Licenses.

Doğan Enerji sells electricity that is harmless to the environment, clean, green and renewable from all the production plants in its portfolio.

Şah WPP

As part of our efforts to reduce carbon emissions, Şah WPP completed the Gold Standard application process. After the second verification in 2018, the company’s mitigation of 901,912 tons of CO2 emissions in 2011-2018 was confirmed. Şah WPP also undertook other various environmental initiatives, such as planting 1,000 trees and providing vehicles, personnel and required materials to the Bursa Directorate of National Parks and Wildlife Protection.

In addition, it installed feedboxes to provide food for birds during winter months, and food for deer was also placed in suitable locations. Since the power plant is located in a forest and wildlife protection area, utmost attention is paid to the protection of the surrounding natural environment. In collaboration with authorized bodies, the management ensures that all operations are carried out in a manner respectful of the environment. Şah WPP received the ISO 14001 Environmental Management System and ISO 50001 Energy Management System certificates following the completion of quality certification processes in accordance with its environmental policy. It also undergoes regular audits. The plant’s other efforts to achieve sustainability have led it to obtain the ISO 9001 Quality Management System, ISO 10002 Customer Complaint Management System, OHSAS 18001 Occupational Health and Safety Management System and ISO 27001 Information Security Management System certificates.

Mersin WPP

As part of efforts to reduce carbon emissions, Mersin WPP completed the Gold Standard application process. After the second verification in 2018, the company’s mitigation of 530,586 tons of CO2 emissions in 2011-2018 was confirmed. Committed to improving the environmental conditions of the surrounding region, Mersin WPP planted saplings in various locations within its operation area. Since the power plant is located near the migration routes of birds, the birds are observed every six months and the findings reported to relevant institutions. To avoid creating any disturbances for nearby villages, noise levels are measured and reported as well. As part of its additional capacity increase efforts, the company received a positive Environmental Impact Assessment (EIA) report and ensured that the necessary actions were carried out so as not to harm the environment.

Local residents were invited to share their complaints and recommendations at the Public Information Meetings held in neighboring villages. Mersin WPP received the ISO 14001 Environmental Management System and ISO 50001 Energy Management System certificates following the completion of its quality certification processes in accordance with its environmental policy. It also undergoes regular audits. The plant’s other efforts to achieve sustainability have led it to obtain the ISO 9001 Quality Management System, ISO 10002 Customer Complaint Management System, OHSAS 18001 Occupational Health and Safety Management System, and ISO 27001 Information Security Management System certificates

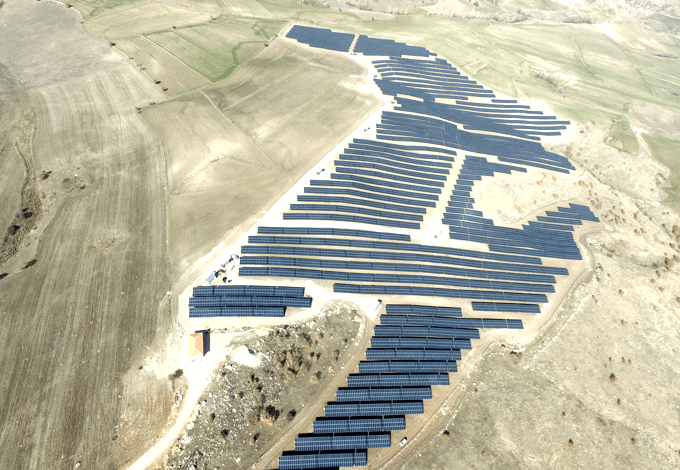

Çorum SPP

As part of its effort to reduce carbon emissions, Çorum SPP launched the Gold Standard application process. Following the process’s completion in 2019, Çorum SPP is expected to reduce 7,880 tons of CO2 emissions annually.

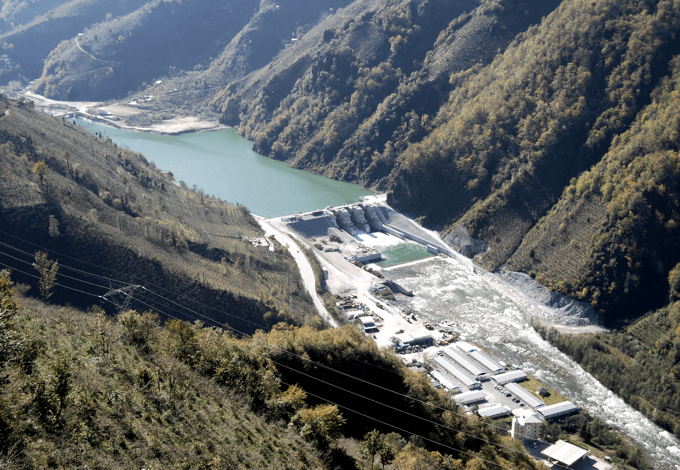

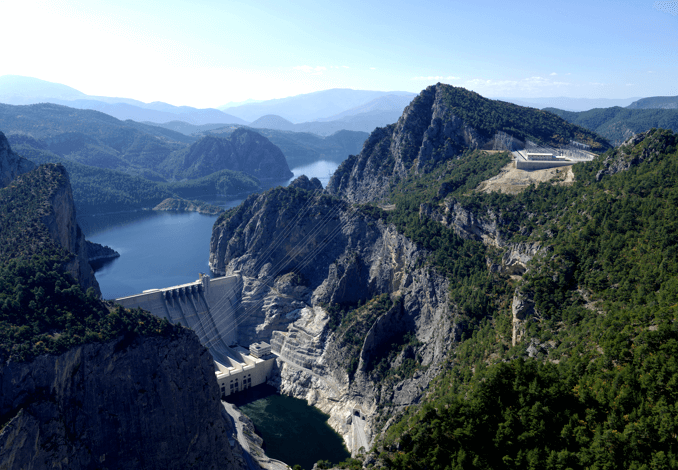

Aslancık

Carbon emission validation at Aslancık HEPP is now complete, but the verification process remains underway. Following the completion of the verification process, Aslancık HEPP expects to find that the company reduced 678,074 tons of CO2 emissions from 2014-2018. After completing its quality compliance processes in 2015-2016, Aslancık Elektrik received ISO 14001 Environmental Management System and ISO 50001 Energy Management System certificates in accordance with its environmental policy.

Boyabat

Following completion of the VCS carbon verification efforts at Boyabat HEPP, a net CO2 emission reduction of 1,885,282 tons is projected for the 2012-2018 period. After completing its quality compliance processes in 2014-2016, Boyabat Elektrik received ISO 14001 Environmental Management System and ISO 50001 Energy Management System certificates in accordance with its environmental policy. Other quality certification efforts for achieving sustainability have allowed Boyabat Elektrik to obtain the ISO 9001 Quality Management System, OHSAS 18001 Occupational Health and Safety Management System, and ISO 27001 Information Security Management System certificates.

Industry

Çelik Halat

Çelik Halat meticulously complies with the Environmental Law as it works consistently to ensure that its operations minimally, and possibly negatively, impact the environment. The environmental permit required under Environmental Law No. 2872 covers the years 2015-2020. Çelik Halat obtains the water for its operations in two main ways: through well water and recycled water. The company has commissioned an Advanced Treatment system to further its efforts to use natural resources more effectively and reduce costs. The wastewater generated through this process is discharged to the ISU channel in a controlled manner, and the ISU also regularly controls it.

The samples taken by controllers meet relevant requirements. Emission Measurements are regularly enforced by authorized institutions to keep the emissions generated during production processes under control in accordance with the relevant legislation. Çelik Halat fulfills its obligations by following all legal regulations related to waste management and carries out the following activities in a systematic manner in order to reduce waste generated by its operations and manage waste effectively:

Çelik Halat is committed to using energy and natural resources as efficiently as possible.

- Sewage sludge classified as nonhazardous is sent to licensed firms under suitable conditions

- All activities related to packaging waste are conducted in cooperation with the Environmental Protection and Packaging Waste Recovery and Recycling Foundation (ÇEVKO)

- Hazardous waste is stored in specially designed temporary containers in areas granted a Temporary Waste Storage Permit, and then sent to licensed disposal firms

- Collection units for battery waste are placed at company offices and specific locations in production areas; the collected batteries are then sent to organizations authorized by the Portable Battery Producers’ and Importers’ Association (TAP)

- Waste oil classified as hazardous or expired is considered 1st Category Waste Oil; such waste oil is either reused by the system and/or sent to licensed recycling facilities

- Assembly units for materials contaminated during the production process have been installed; materials collected from these areas are sent to licensed organizations

- All waste is meticulously collected in the facility, sorted and disposed of in accordance with relevant legislation Striving to utilize energy and natural resources in the most efficient manner, Çelik Halat’s use of electricity, natural gas and water is closely monitored and excess use is prevented. Furthermore, the company regularly implements technical improvements to ensure efficiency. Ensuring that management teams and all employees embrace the company’s approach to the environment, Çelik Halat provides new operators and white-collar employees with on-the-job training on environment management systems. Additionally, each employee is required to participate in Environmental Awareness-Raising training programs at least once a year. On issues related to environmental regulations, the authorized expert personnel of an environmental consultancy firm retained by Çelik Halat supports the company. This consulting firm also ensures regular internal audits at Çelik Halat. The amount of water recycled by the company has increased by 10.3% year-over-year to 77,376 m3 in 2018. In parallel to the rise in production, the total amount of water consumed increased by 26.2% to 101,779 m3. The total amount of electricity consumed by Çelik Halat measured 29,218 MWh in 2018, a level aligned with the previous year. The amount of electricity recycled by the cogeneration unit decreased by 19.6% year-over-year and reached 9,611 MWh in 2018. In 2018, Çelik Halat recycled 15 tons of paper.

Ditaş

Ditaş carries out its production processes with a strong environmental sensitivity and committedly fulfills its environmental obligations. Reducing its water consumption by 1% year-over-year, Ditaş consumed 56,340 m3 of water in 2018 and also recycled 14,950 m3 of water, causing its 5-year water recycling performance to reach 60,176 m3. The ratio of recycled water to total consumption was 27% in 2018. The total amount of electricity consumed by the company decreased by 3.6% year-over-year to 9,779 MWh. In 2018, a total of 38,024 kg of paper, cardboard and plastic waste generated at the factory was sent to recycling companies, thus saving approximately 647 trees. After over 20 years of operations with quality and environmental management certificates, Ditaş successfully passed its ISO/TS 16949:2009 Quality Management Certificate audit in 2017 and extended its ISO certificate for three years. Following its audit in May 2018, the ISO Certificate has been replaced with the IATF 16949: 2016 Quality Management Certificate. Ditaş extended its existing ISO 14001: 2004 Environmental Management System Certificate in 2017, and qualified to receive the ISO 14001: 2015 Environmental Management System Certificate. The ISO: 14001: 2015 Environmental Management System interim audit, conducted on November 15, 2018, was successful and the certificate extended.

Ditaş also holds a FORD Q1 quality certification. In 2016, the company began conducting its internal and external process audits in accordance with the German VDA 6.3 standard, and successfully passed these audits, including the Volkswagen Group. Following MAN's VDA 6.3 audit, Ditaş qualified to become a global supplier of MAN in 2017. In 2018, Ditaş provided a total of 2,523 hours of occupational health and safety training for 397 people.

Media

Doğan Burda

Continuing its eco-friendly approach, Doğan Burda reduced its total electricity consumption by 12% to 160,826 kWh and recycled 964 tons of paper in 2018. Throughout the year, Doğan Burda magazines extensively featured sustainability, environment, nature and fashion related issues.

Doğan Burda reduced its total electricity consumption by 12% to 160,826 KWH and recycled 964 tons of paper in 2018.

Tourism

Milta Bodrum

Marina

Milta Bodrum Marina, an international marina, has received the Blue Flag award every year since 1997, recognizing its high standards, modern infrastructure and in-demand services. The recipient of the European Union’s Five Gold Anchors Award, Milta Bodrum Marina also once again won Turkey’s Best Environmental Awareness and Training Activities Award from the Foundation for Environmental Education (TURÇEV) in 2018. Also in 2018, Milta Bodrum Marina recycled 10,799 m3 of water, amounting to 43.8% of its total water consumption. While its total electricity consumption increased by 1.5% year-over-year in 2018, Milta Bodrum Marina reduced its total water consumption by 13.7% to 24,670 m3. Milta Bodrum Marina recycled 23.7 kg of waste paper in 2018. Its total waste measured 6,196 tons, while the total amount disposed of measured 5.5 tons.

Double Tree by Hilton Bodrum Marina Vista

After adding additional collectors to its solar power system in 2016, Double Tree by Hilton Bodrum Marina Vista began employing a heating pump and, as a result, completely eliminated the consumption of diesel fuel. In addition to equipping rooms and common areas with led and energy saving bulbs, Double Tree by Hilton Bodrum Marina Vista collects battery waste in special containers and delivers these to the Association of Portable Battery Manufacturers (TAP) and environmental units of the municipality for proper disposal. In 2018, Double Tree by Hilton Bodrum Marina Vista recycled 3,764 kg of paper and its facilities consumed a total of 1,253 tons of water.

Committed to generating sustainability as Turkey continues its modernization, Doğan Holding takes a corporate social responsibility approach focused on creating lasting added value.

The Holding, in cooperation with shareholders and the Aydın Doğan Foundation, undertakes long-term social responsibility projects in the areas of education, culture and the arts, healthcare and the environment. By encouraging voluntary participation from its employees, Doğan Holding increases the overall social benefit of its social responsibility projects.